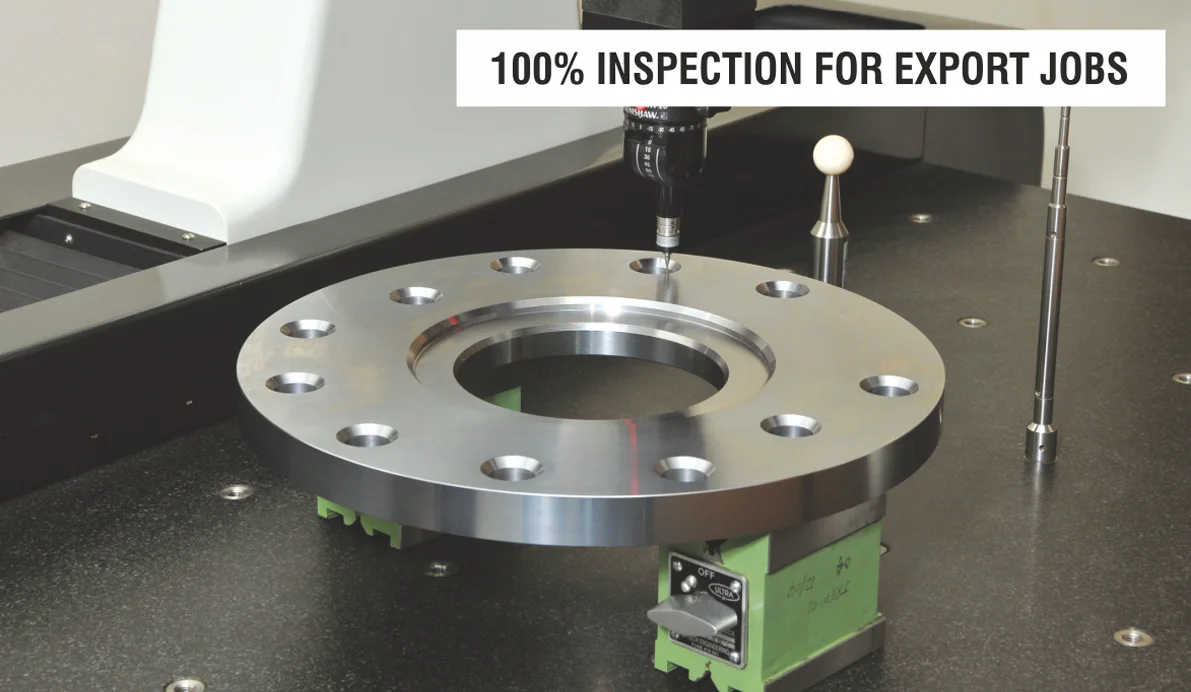

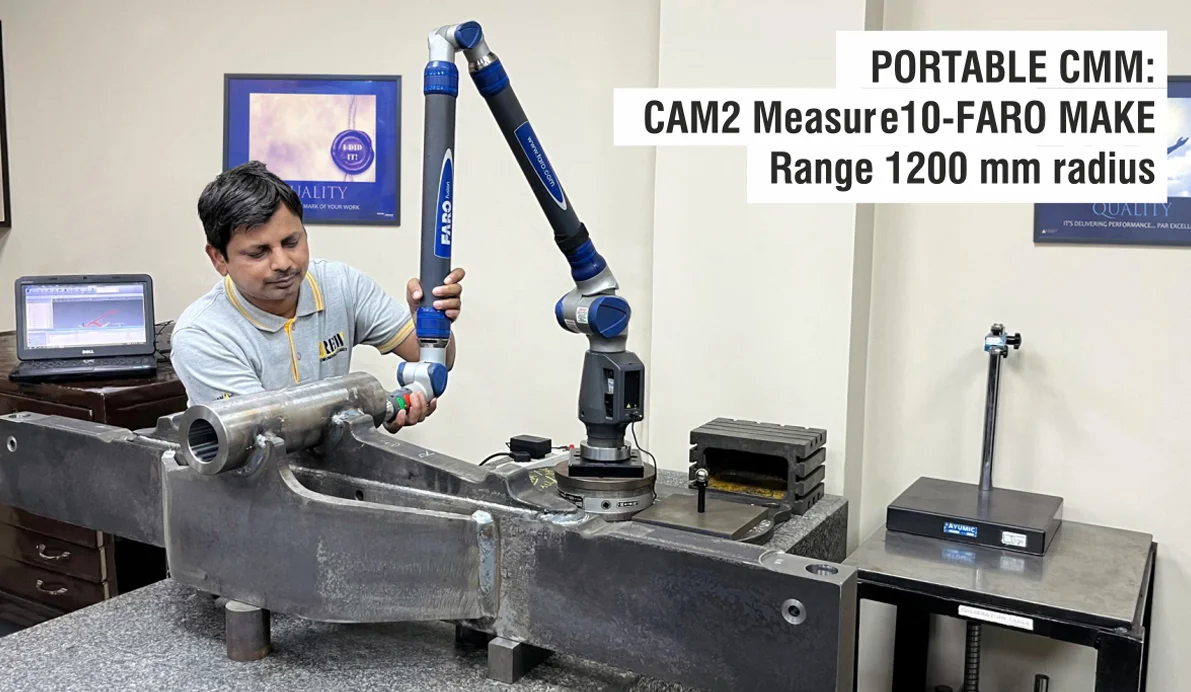

Integrated Quality Practices

Each of our manufacturing units is supported by a dedicated Quality Assurance (QA) department, led by experienced Senior Managers and staffed with skilled quality engineers. These teams are equipped with cutting-edge tools and infrastructure to monitor and maintain the highest quality standards. Our QA teams report directly to the top management, ensuring seamless communication and alignment with our strategic goals.