Mohali Facilities

First Facility

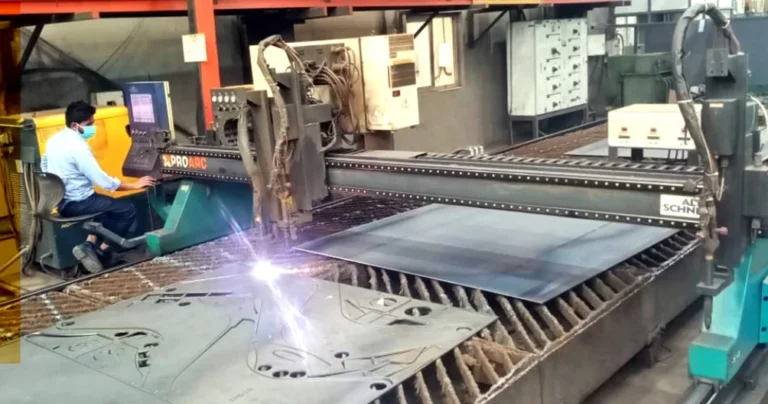

- Dedicated to manufacturing axle weld assemblies, forklift mast assemblies, and specialized machine components.

- Equipped with a comprehensive range of advanced machinery, including CNC Profile Cutting Machines, Horizontal Boring Machines, Surface Grinders, Vertical and Horizontal Machining Centers, VTLs, and CNC Turning Centers.

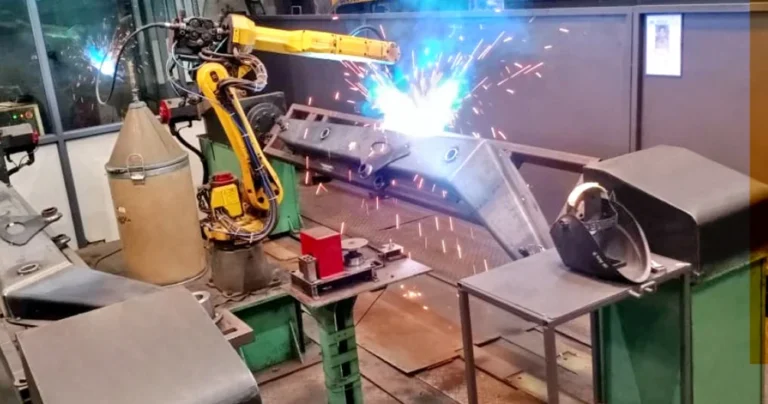

Second Facility

- Exclusively focused on the production of electric stackers.

- Equipped with specialized equipment for precision fabrication, machining, and assembly to ensure high-quality products tailored for this niche market.